Air conditioning is an indispensable electrical appliance in the interior, especially in the summer, the usage rate is extremely high, and the annual demand is also increasing. A certain manufacturer of air conditioners has found that we want to use 3D scanners to scan and test the air conditioning components, and obtain accurate data for later design and production, so that the overall design is more reasonable, enhance the competitiveness of air conditioners in the market, and improve sales. the amount.

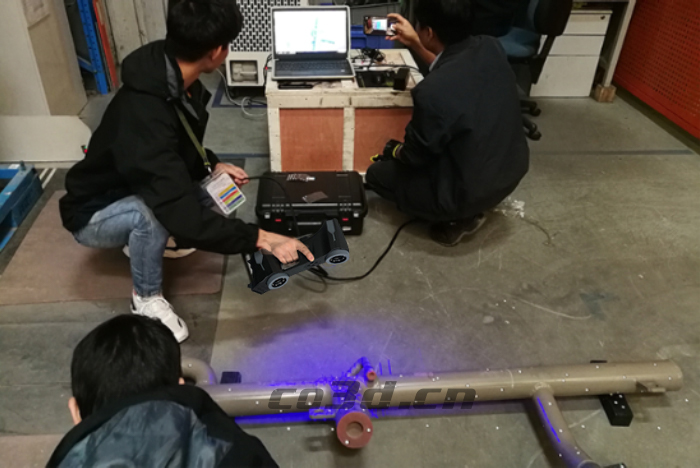

Air conditioning pipeline site scan

Practical problems

It is necessary to measure the size and parallelism of the air conditioning pipe to compare the previous data to see if there is any deformation. According to the overall assembly of the air conditioner, the air conditioning pipe is bulky and irregular in shape.

Air conditioning pipeline site scan

In other ways, the measurement results were not satisfactory, and the accurate 3D data could not be used for comparative analysis. Can not solve the problems faced by customers.

Air conditioning pipeline site scan

Holon solutions

To solve the problem of measuring the size and parallelism of air conditioning pipes, our engineers use the handheld 3D scanner HOLON760, which uses a blue laser line. Use the scanner to quickly and comprehensively scan to obtain high-precision 3D data of the workpiece. The scanning time is short, the speed is extremely fast, and the volume accuracy of the single machine is high. It effectively solves the problems encountered during the scanning process, eliminating the need to prepare for the preliminary work, saving time and improving work efficiency.

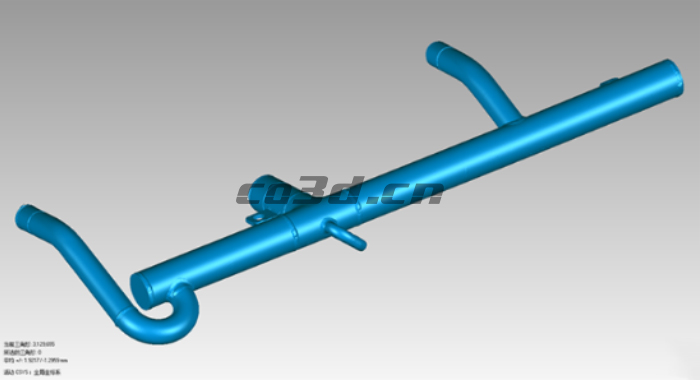

Air conditioning pipeline STL data map

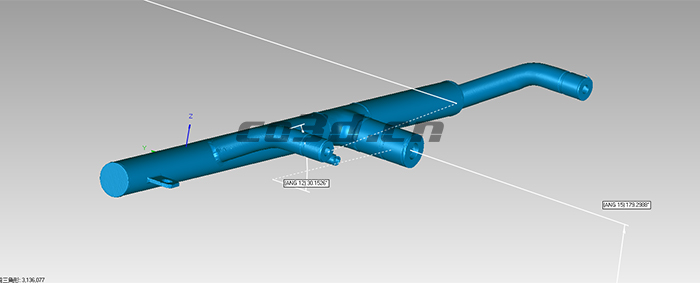

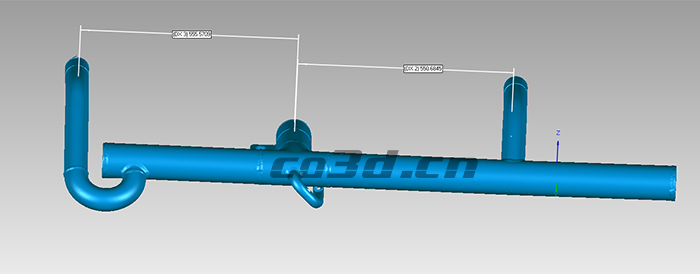

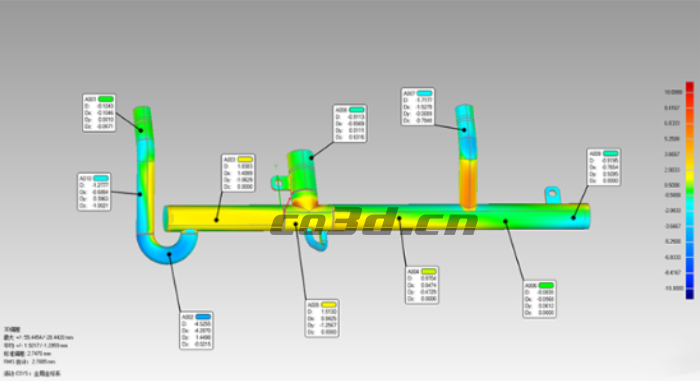

The scan acquisition data is imported into the 3D inspection software for comparison and analysis with the original digital model. The scanning effect of the details is very good, the data is complete and the precision is high. The customer can intuitively know the deviation between the size and the parallelism of the air conditioning pipe through analysis and comparison. The customer is very satisfied with the scan data and provides a data reference for the later work.

Air conditioning pipeline STL data map

Air conditioning pipeline STL data map

Air conditioning pipeline reverse data map